Howdy Folks!

Welcome back to the campfire. A few weeks back we discovered a truly eye opening issue. It started when we built a prototype cardboard shipping box for the HOWL R4. The simplest way to test a box is to ship it and see what happens. So we sent a HOWL from Colorado to a parts vendor in Chicago that we were vetting.

The box arrived looking beat up. The unit inside was still in good shape, though. So far so good. But when they sent it back to us... what Fed-Ex brought through our door was a disaster.

The box was completely destroyed, and the R4’s front legs and carry handle were bent beyond usability.

It would be pretty easy to just make a better box. But the HOWL Campfire is supposed to take decades of abuse in the outdoors. The fact that it got damaged in shipping was entirely unacceptable.

So we tried to replicate the conditions of the failure. The carnage suggested that the box had been dropped or thrown by handlers standing in the back of a semi trailer, down onto concrete. Judging by the number of impact points, this occurred multiple times.

In addition to the leg damage, we also found that a couple internal rivets had sheared.

But here’s what was interesting: only the front legs bent, while the rear legs remained solid.

So that’s where we started our tests. We dropped the damaged unit directly onto its back legs, then did it again from higher up, then again from higher still. We kept smashing these rear legs against our concrete shop floors, and they held up perfectly.

[The rear legs remained undamaged in drops from 7 feet. The LipCurl handle flying off was somewhat expected, since it was poorly installed.]

So that was the key: The rear legs had a welded steel corner brace configuration, while the front legs were braced only with aluminum and bolts. This made them significantly weaker than we expected.

To give them the needed strength, we added a welded steel corner brace. The front legs now structurally mirror the rear legs.

The brace we designed tucks behind the orange front panel, and is stitch welded in from top to bottom. With this reinforcement, we resumed testing, dropping the unit from increasing heights directly onto the formerly weak front legs. Boom, problem solved.

During this round of drop tests, we were also testing a new set of rivets. The ones that had sheared internally were aluminum. In the new design, we replaced them with steel. After fully testing the front legs, we then dropped the unit onto concrete repeatedly at different angles, finding that these new rivets also held up perfectly.

[Testing different drop angles.]

This round of more intense testing revealed a new problem

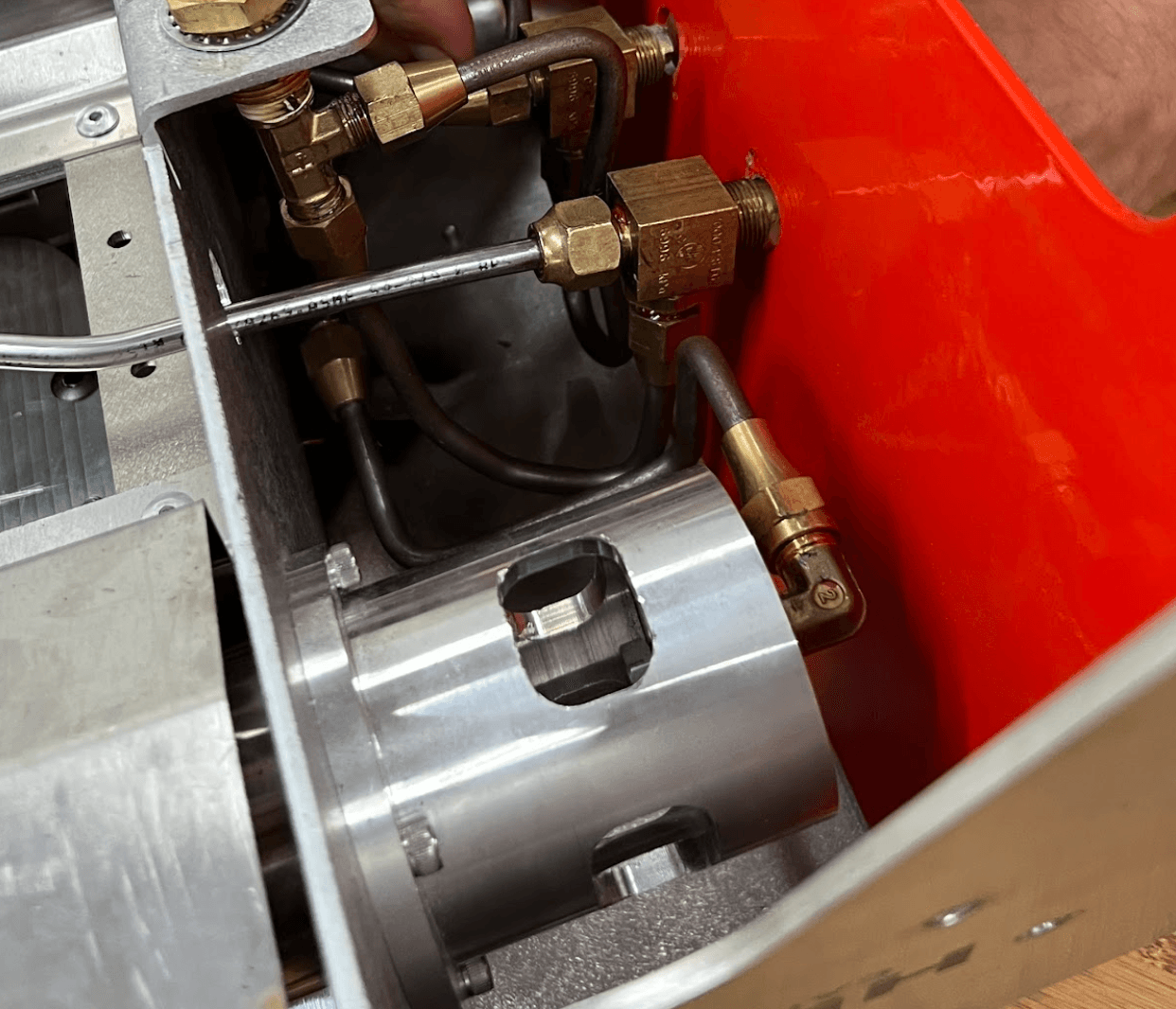

As we increased the height of our drop tests, we saw that the BarCoal tubes were shifting out of position.

The heavy steel tubes were suspended inside the unit from the lighter-guage aluminum heat reflector shields. With repeated impacts, the shields were starting to deform under the momentum of the heat tubes. It took dozens of large drops, but we the BarCoal attachment points finally ripped out of the frame.

So we designed a new structural brace for the BarCoal. This webbed piece of plate metal means the tubes no longer hang from the heat shields. Instead they are locked directly into the mainframe. Another round of drop tests confirmed it: problem solved.

The final results?

The new frame configuration shows zero signs of damage when dropped from 5 feet onto concrete

It sustains minor dents, yet remains perfectly functional, after dropping from 6 feet. That means you can party hard with your HOWL and take it to the wildest places imaginable.

[Caption] A 5-foot drop test.

[Caption] A 6-foot drop test.

With these problems solved, there’s just one big question still hanging out there: Will we pass our safety certification with UL?

We should have an update on that for you very soon. Fingers crossed!

Keep carrying the fire,

— Randall, Alex, Kelly, Nicholas, and Diego