Welcome back to the campfire, folks!

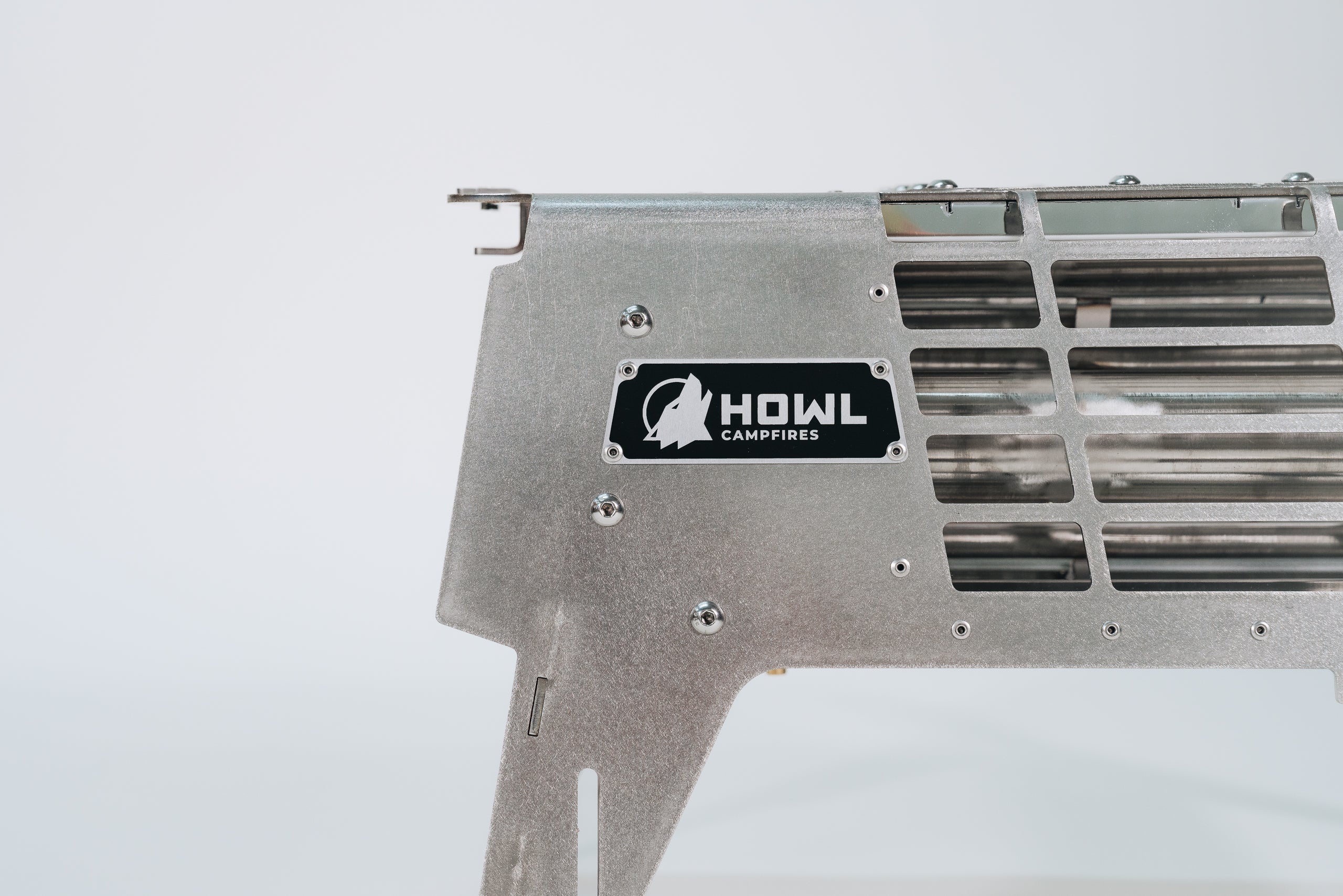

Our certification is finally moving, and Underwriters Laboratories (UL) will be doing the testing. Check out the Final Pre Production Sample we sent them, after first taking it on a testing trip in Moab.

Can we just say how proud we are of this campfire? The beauty, functionality, and craftsmanship so completely exceeds what we thought was possible when we started out on this journey. We cannot wait to put this thing in your hands.

But before you can have it, there are two hurdles we need to clear:

- We need to have it certified to the ANSI Safety Standard for the Outdoor Decorative Gas Appliance category (ANSI Z21.97)

- We need to hone our manufacturing processes so we can build it here in the US, while doing everything possible to sell it at a reasonable price.

Here’s what’s taking so long:

To pass the upcoming battery of tests that UL is requiring, we’ve had to redesign an enormous number of components. Of course, every part works in harmony, so this has essentially been a ground-up redesign sprint.

In all our revisions, we’ve found ways to make the HOWL even better – especially for hardcore use cases.

The HOWL can now withstand absolutely silly conditions. It is the only campfire – wood or propane – that can immediately make you warm when every log is soaked, or when your camp is buried in snow, or when hurricane winds make building a fire impossible.

It lights immediately in the middle of a PNW downpour. It keeps you warm in Colorado’s highest campsites. It takes a beating on Utah’s gnarliest desert trails. It cranks heat in Montana’s rock splitting cold. It’s unbothered by the sideways hail of the high-plains.

Whatever the conditions, this thing keeps you warm, while still keeping the ground cool – a first in the history of campfires.

Now if you’ve been here a while, you already know what it took to get a propane fire pit to perform all these feats: GRIT. It has been nothing but test, fail, redesign, repeat, repeat, repeat.

To give you an idea, we started writing out the list of the latest changes.

- The frame is now thinner and more durable. In earlier prototypes, it was made from plate aluminum. Going into production, it is now 11-gauge 304 stainless steel. In addition to being more durable, steel also stays cooler when subjected to extreme heat.

- The shape of the frame has been extended slightly to incorporate the twin jet design. This protects the BarCoal tubes from abuse, and keeps your clothes and skin a little farther from that glowing hot steel.

- The shape of the EchoHeat reflector shield has been updated and optimized for the twin jet system. This ensures all three sides are properly aiming that thigh-melting IR light.

- The internal heat shield has been switched from steel to aluminum, and we added an air gap to dissipate heat. This allows us to keep the heat where we want it, without overheating the control box or legs of the frame.

- The A-Flame burner plate has been domed up in the middle for drainage, and we’ve added drainage ports at the edges. That way the A-Flame keeps its tall, bright flames, even in a heavy downpour.

- The BarCoal tubes have also gotten a drainage port upgrade. Even after hours of torrential rain, the BarCoals lights right up and makes you warm – as per usual.

- The BarCoal system has been refined to save weight. This makes carrying your HOWL much easier.

- The A-Flame WindScreen is now removable, making it easy to clean if you accidentally spill something that won’t just burn off.

- The Kickstand and StrapLock slots have been completely redesigned, making it easier to marry the fire pit and tank for strapping down in a truck. (If you love highspeed offroading like we do, this is a must-have feature)

- The LipCurl handle has been updated to stay cool to the touch and keep your hand in a comfortable position while carrying.

- The gas plumbing system has long been a challenge. Most propane appliances aren’t designed to take serious off-road vibration and impacts. After testing multiple iterations, we found a pressurized tubing system used in F-16s that holds tight no matter what.

- The frame’s base plate has been switched to a lighter gauge aluminum to save weight.

- Each fastener and connection has been optimized for strength, shear, and heat tolerance to maximize the life of the product.

So we changed everything again… Now what?

Now we have to go pass our certification tests. At the end of the week, we’re driving two pre-production samples up to Underwriters Laboratories (UL) in Chicago. If we’ve done our jobs as well as we think we have, we’ll pass the ANSI Z21.97 Decorative Gas Appliance Standard with flying colors.

While they’re running tests, we’ll have our heads down in a sprint to finalize the tooling and assembly processes. That way we can start cutting metal in our Colorado factory as soon as they flash the green light.

“Just tell me when I can buy the thing!”

You got it! If the testing and pre-manufacturing phases go to plan, we’ll open up orders for the first batch of HOWL Campfires in June.

This will be a small batch. We’re just starting out, and we need to ensure the highest level of production quality possible. Making limited numbers, one batch at a time, allows us to make sure every detail is exactly as it should be, so you’ll have a campfire you’re delighted with.

Thank you so much for sticking with us. It’s been a long road, and your excitement continues to keep us going. The HOWL is becoming a reality, and that is 100% thanks to YOU!!

Keep carrying the fire,

— Randall, Alex, Kelly, Nicholas, and Diego