We lit it. Waited a very long time but never did feel much. Eventually we killed it. It felt like we’d wasted a year of our lives.

Welcome back to the Campfire.

We f*cked up royally.

Just a few weeks ago we were sitting with our new manufacturing partners down in Texas, looking at a very failed prototype. That chunk of metal represented a whole year of nonstop design and engineering, yet here it was, nothing more than a door prop or a really big paperweight.

Two days before, we strolled into their metal shop ready to complete the assembly of the HOWL V2 pre-production prototype. This assembly test was supposed to be the final step before ordering parts, inking a contract for our first production run, and announcing to you guys with much stoke and fanfare that pre-orders were now, finally, OPEN.

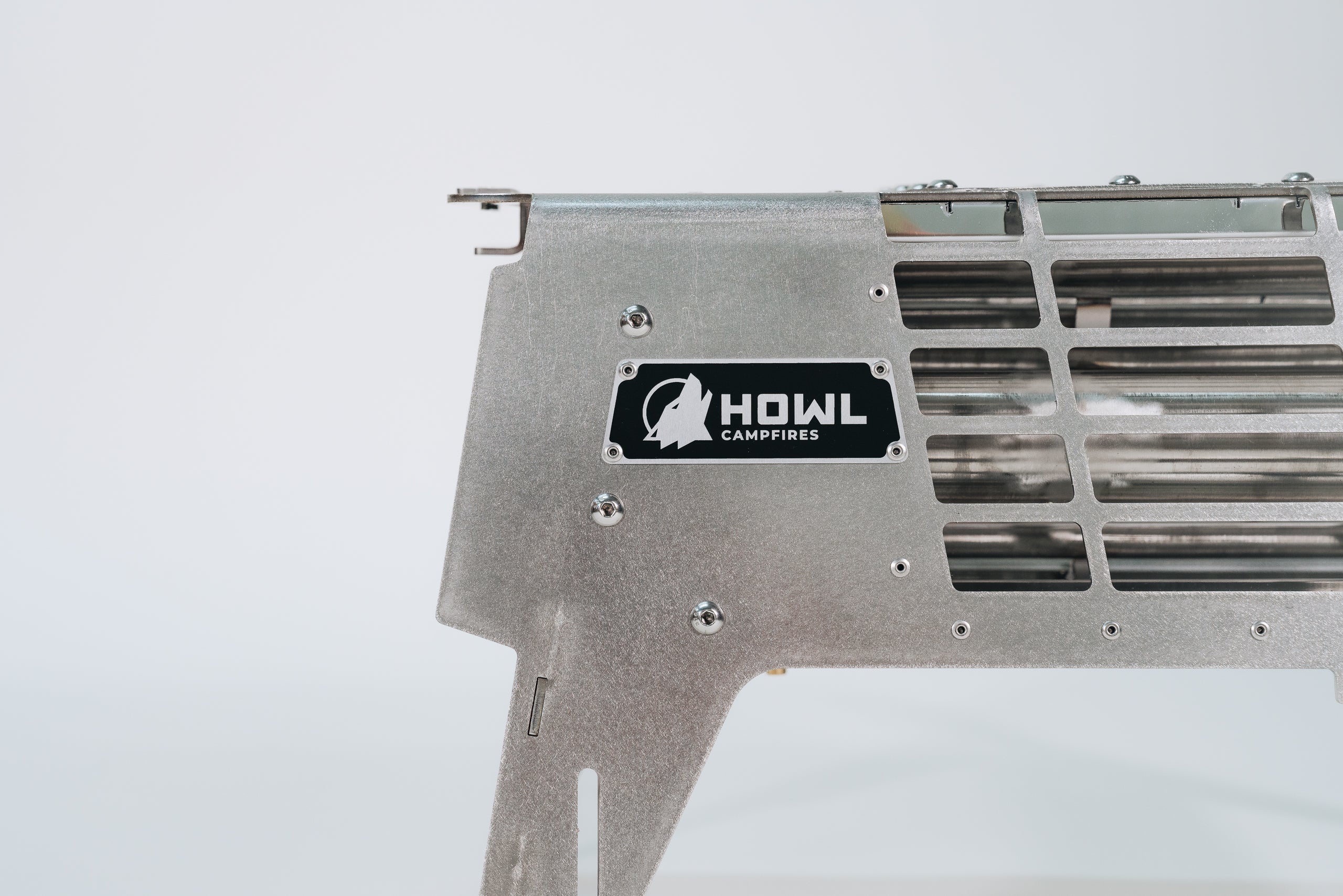

[The V2 Prototype, functioning as intended during a test burn at home.]

But here’s what happened instead

The first day at the shop went well. It was our first time handling the fully built mainframe and inspecting all the internal components we’d been obsessively tweaking in CAD for months. The whole package felt cohesive, thoughtful, and intuitive. The size and finishes were perfect.

Testing the HOWL's packability with the tank got us amped. From the beginning we’d been working to integrate the 20-pound propane tank into the legs, and here it was, functioning exactly as designed!

[Testing the tank integration, and testing the mainframe strap lock slots using ski straps]

Sure, we had some hiccups in making some of the parts. Like, it turns out ¼ inch aluminum doesn't like to bend at 90 degree angles unless there’s a lot of material there to stretch, which we didn't have. The narrow fenestrations between the windows on the mainframe just wouldn’t hold shape in the press brake machine. We knew those bends were a gamble. We lost the bet, but we already had backup plans.

On Day 2, we dialed in the alignment of the smaller components. We added in the propane controls, bent the copper gas lines for fit, and checked for leaks across the system. Everything was going according to plan.

[Assembling propane hardware.]

At 5p on Day 2, after one last leak check, we attached the propane tank and readied the fire extinguishers.

At this point, igniting the fire pit was a mere formality. We had run numerous tests on both the BarCoal and the A-Flame burner assemblies that were now seated inside the device. They both functioned flawlessly in our external tests. The only difference now was that they were assembled into the frame. The test burn was supposed to be a systems check, not a product validation.

[Final soapy water leak check before test burn.]

“3,2,1. Gas on… And lighting,” our lead engineer said.

The BarCoal burner started up easily, evidenced by the low rhythmic hum of propane burning hot inside the tube.

Up top, the flames leapt tall and bright from the A-Flame Burner.

It was a warm fall day at 76 degrees, and we waited silently for the BarCoal to reach temperature. But it was taking too long.

Looking around, you could see it written on everyone's faces: “We should be sweating by now. Where is the heat?”

“Give it a minute,” said our lead engineer. We waited a very long time, but never did feel much. Eventually, we killed it.

The trip home was agonizing. It felt like we’d just wasted a year of our lives.

Replicating the heat of the campfire experience was the whole point. The world does not need yet another cold, decorative propane fire pit, and there’s no way we could let you folks buy this thing without it being actually warm.

So why the f*ck wasn't it working? We tested it dozens of times before assembly, and it worked every time. Why not now?

[Baffle testing.]

A week later we were still tinkering with the device, pulling it apart, tweaking one variable, putting it back together, firing it up, repeating. We did this a couple hundred times. Every time, it seemed the part at the heart of our problem was the baffle.

We were baffled

The BarCoal’s baffle is a strip of metal that sits inside the tube, adding back pressure and turbulence. It helps burn any uncombusted fuel, and it pushes heat from the exhaust gas into the tube walls, which glow to produce the IR rays that you can feel.

But its most important function is that it keeps the combustion stable.

[The flippin’ baffle that worked… and then failed.]

With the BarCoal’s U-shaped bent tube design, the baffle needs to have an incredibly precise shape, size, and placement. Just a few millimeters deviation in any direction causes the whole system to fall outside the working parameters. When that happens, the tube goes cold, burns out, or you just get a lapping, lazy blue flame at the exhaust.

In our hundreds of tests of the fully-assembled V2 Prototype, we only got the BarCoal to work properly a handful of times. One time, we got it burning perfectly for 45 minutes, turned it off, let it cool, *changed nothing* and relit it – only to have it not work at all. It was maddening.

[Pulling out parts for testing.]

How did we get it to work so consistently before?

The best we can figure is that it was sheer dumb luck. We accidentally nailed a functional baffle configuration in our first couple tries, and then it kept working through dozens of test burns, so we didn’t give it much more thought.

Later, when we added the V2 pre-production components, we changed things just enough that the baffle that once worked flawlessly no longer worked at all. And after that, we couldn’t seem to find the balance point again between back-pressure, air flow, laminarity, and turbulence.

[Drilling out rivets for disassembly.]

What's crazy is that you can get a baffle to work brilliantly when the device is cold, only to have it fail miserably a few minutes later.

That’s because every second the BarCoal is working, it’s getting hotter, and the heat causes the system to expand and change shape. So this is the challenge we’re up against: we have to build a baffle that keeps the airflow constant whether the metal is -20º F or 2,000º F.

Making a hot propane fire pit is hard. But not impossible.

Sometimes during our hundreds of trials, we'd stumble upon that one perfectly shaped strip of sheet metal. We'd flick the lighter and the BarCoal would leap to life, glowing and whispering and humming. The tube would glow, causing our body's molecules to dance faster and faster as we felt the warmth rising against the cold. The BarCoal would keep holding stable.

And when that happened, it felt like we'd been let in on a great, old secret. Maybe that’s how our ancestors felt when, deep in some cave, they discovered they could make fire, control it, contain it, and stay warm by it. It is a wild feeling.

[Device upside down and disassembled for rapid testing. This is an ideal BarCoal burn, hot and bright.]

That’s how it felt on a late October day when the wind ripped the last yellow leaves from the trees. The sky was dark and gray, and the BarCoal was glowing bright amber. With our eyes closed, it felt like we were standing by a wood fire in an old forest.

We stood there soaking in the warmth, listening to the BarCoal, listening to the wind. The sky then released the season’s first snow, and each snowflake sizzled against the amber tube.

This is what we designed it to be.

In the weeks since the snafu in Texas, we’ve gotten very serious about baffles. We’ve tapped some brilliant fluid dynamics engineers to build computer models of how gasses flow through the BarCoal system. Soon we'll be testing those models against reality, and using the data to make a baffle that keeps the burn stable across a whole range of environmental factors.

So where does that leave you, our someday customer?

The next two months will be an intense, all-hands-on-deck engineering sprint to develop the perfect baffle.

Once that’s solved, we’ll shift focus to tweaking V2’s design to make it faster to manufacture. The good news is that the list of tweaks is short, with not too many unknown variables, so we think we’ll be ready to spin up manufacturing this March.

**That means the HOWL Campfire could start shipping as soon as April 2023, just in time for the summer season.**

[Yeah, that’ll melt your thighs. Operating upside down and disassembled for rapid testing.]

But we have a lot of work to do between now and then, and we need help.

We’re looking to hire a full-time manufacturing engineer to come join our campfire. If you know a brilliant engineer who wants to help keep the forest and campfire alive – preferably with experience in metals, combustion, regulatory compliance, or technical outdoor gear – please tell them about us!

We live in a weird time where conversations aren’t always face to face, and instead of voices, the feedback comes in clicks and pixels. Well, we see your responses. We see your email opens and likes, your comments and shares, and it means the world to us. Thank you for continuing with us on this journey. It's comforting to know we’re not just designing out into the void.

Keep carrying the fire,

– Randall, Kelly, Nicholas, and Alex